Die Sets: Build, Buy or DIY?

Ancient Greeks put metal blanks between two forms and hit it with a heavy object to create coins. The first patent for punching sheet metal was issued in 1796 to a French toolmaker, and the first progressive die is attributed to Ed Stouten in 1953. Tool and die sets continue to evolve and improve, and are used by millions of metal fabricators to form sheets of metal into objects, shapes and parts. Is it better to build a custom die set for your needs, buy one, either custom-designed or catalog, or DIY from parts? Let’s look at the options.

Build

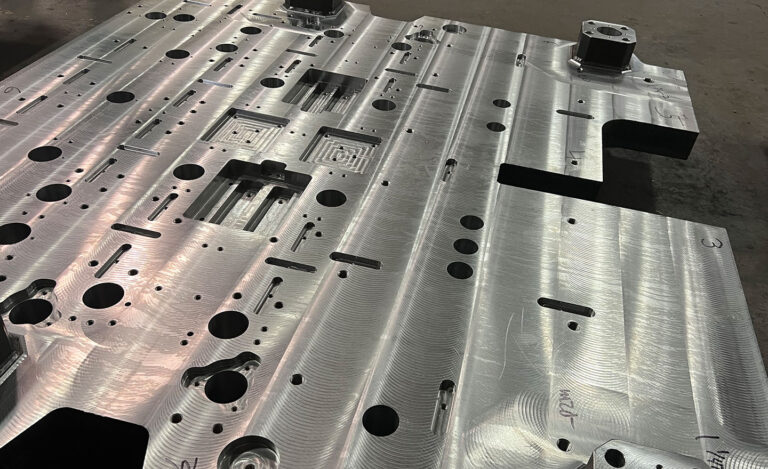

Customers opt to build their die sets in-house for a number of reasons. It can be a matter of economics, and a way to keep workers and machines operating during lean times. Others may buy plates that fit on their CNC machines from a local supplier, purchase components from another supplier, such as Anchor Danly and then machine the die set in one or two setups, giving them control over the machining and any last-minute changes that may be required.

In other instances, customers choose to build because the dies require a level of precision difficult to mass-produce, such as for “dies that stamp thin-gauge materials (perhaps 0.010” or less) or that run at high speeds (in excess of 200 spm) or both…In some extreme cases, the holes for the guide elements in the upper shoe and lower shoe may even be line-bored simultaneously (with the two die shoes clamped together). This results in zero positional variation between upper and lower bores,” said Ray Osborne, Director, New Business & Product Development, Anchor Danly.

Pros

Can result in precision, zero variation and a die set custom-made for customer’s needs.

Keeps the facility operating in slow times.

May provide some cost savings.

May have a faster timeline than custom solutions.

Cons

The DIY companies’ high-skilled labor is being used for low-skilled tasks. This could result in job dissatisfaction and turnover if continued over the long-term.

High value machines that are expensive to operate are being used for lower margin work.

The cost to build one-off die sets will generally be more than purchasing the same set from a specialty fabricator who can take advantage of economies of scale and production expertise.

Many dies require specialized equipment that many smaller facilities may not own.

“A customer in Wichita, Kansas once told me they tried building their own die sets a couple of times. However, they couldn’t do it as cost-effectively…they aren’t properly tooled for this kind of work. I liken this to a mechanic that works on cars. They have the tools to fix or rebuild cars, but to make a brand new car just isn’t possible,” added Jim Schramm, Regional Sales Manager, Anchor Danly.

Buy

For many customers, it makes economic sense to buy die sets from a metal fabricator, either as a standard catalog kit, or a custom-designed solution. “Some customers buy a fully machined die set that they have to assemble the details on. This reduces the time they have to design the die as it needs to be completed before they order it,” said John Coppolino, Territory Manager, Anchor Danly.

“Our customers are looking for very precise tolerances for automatic lineup between top and bottom die sets. Anchor Danly uses probes to ensure tight tolerance between upper and lower dies. For keys, pockets, dowels, pins and bushings, we can put out a report from the machine to confirm we are in tolerance,” said Nick Clarke, Plant Manager, Anchor Danly.

Pros

Standard catalog die sets are manufactured to standard dimensions with respect to pin size, location and steel thickness.

Standard die set components are often interchangeable with other sets of same dimensions.

Standard die sets can be a cost-effective solution due to economies of scale, volume and expertise.

Custom solutions benefit from the level of expertise available, and knowledge of things customers need to consider that customers may be unaware of.

Proof of concept, proof of principle prototyping available with enhanced reporting and capabilities.

Cons

Custom solutions can take longer than off-the-shelf from design to final product. Turnaround times vary depending on complexity of order.

One-off custom die set may be too costly to custom design.

DIY

DIY, or do-it-yourself, is a misnomer when it comes to die sets. Rather than building the die set completely, customers may buy a simple die set, or buy components and assemble it. “Customers may buy the simple die set, then disassemble it to put on their mill for machining. While buying the die set reduces the amount of purchase orders they cut, if they order the components not in a die set, they need to determine elements like the correct ball bearing components. When Anchor Danly builds a set, we know precisely which components will fit,’ said Coppolino.

Osborne added, “There is some inherent benefit to installing guide component bores on the same machine, during the same setup as the rest of the machined die shoe features. The workpiece is already located in 3D space and clamped securely, so it’s more efficient to do all of the machining at once. Single setup processing also eliminates the possibility of slight errors that may occur during multiple setups, and keeps the machining of all features constrained within the limitations and capabilities of a single piece of equipment.”

Pros

DIY can offer a “best of both worlds” option; customers can purchase a standard die set, and then tweak or customize it for their specific needs.

May shorten the timeline that a custom solution would take.

Cons

Need expertise to ensure the various components will work together as intended and required.

May still require custom machining that facility may not be set up for.

May end up being more costly, time-consuming than a custom solution.

“While manufacturers are always trying to be more lean, the economics may not be right to build one die-set. Customers often say they cannot produce a die set (even at our internal price, wiith the time and effort) for less than buying it from Anchor Danly. I could probably wire my house, but it would be an economically terrible idea,” said Paul Brisebois, President, Anchor Danly.

Whether customers choose to build, buy or DIY, Anchor Danly has the expertise, product and reputation to meet any and all die set needs.

Contact us for more information if you are looking for a custom die, standard die or die components. We can help.